Our capability

See PCB Capability

Atom Sourcing supports 99% of challenging boards you can imagine, from regular prototype PCBs to most sophisticated layer stack ups.

| Type | Description | Parameter |

Rigid

|

Layers | 2L-40L |

| Thickness | 0.2mm-8.0mm | |

| Max size(1L-2L) | 600mm*1200mm | |

| Max Size(4L-6L) | 600mm*900mm | |

| Max size (8L and above) | 600mm*600mm | |

| inner layer line width/line clearance | 3mil/3mil | |

| out layer line width/line clearance | 2.5mil/2.5mil | |

| Aspect ratio | 18/1 | |

| Min. hole size | 4mil | |

| Max copper thickness | 20oz | |

| Impedance control tolerance | +/-10% | |

| Warp and Twist | 0,70% | |

| Outline Tolerance | +/-2mil | |

| Surface finishing we can do | HAL/HAS-LF/ENIG/OSP/Tin | |

| Surface finishing we can support | Flash gold/ Golden finger/ENPIG |

See HDI Capability

High Density Interconnect board

As electronic components are becoming smaller and more lightweight, yet still demanding better performance, HDI board is becoming the fastest growing section in board manufacture.

HDI PCBs are characterized by high-density attributes including laser micro vias, fine lines and high performance thin materials. They also contain blind and/or buried vias and often contain microvias of .006 or less in diameter.

Atom Sourcing handles HDI board with the most advanced equipments and very well trained engineers.

| Type | Description | Parameters | ||

| HDI | 3+C+3 | support bulk production | ||

| 4+C+4 | prototype small qty only | |||

| Buried vias laser drill | support bulk production | |||

| Min laser drill hole size | 3mil | |||

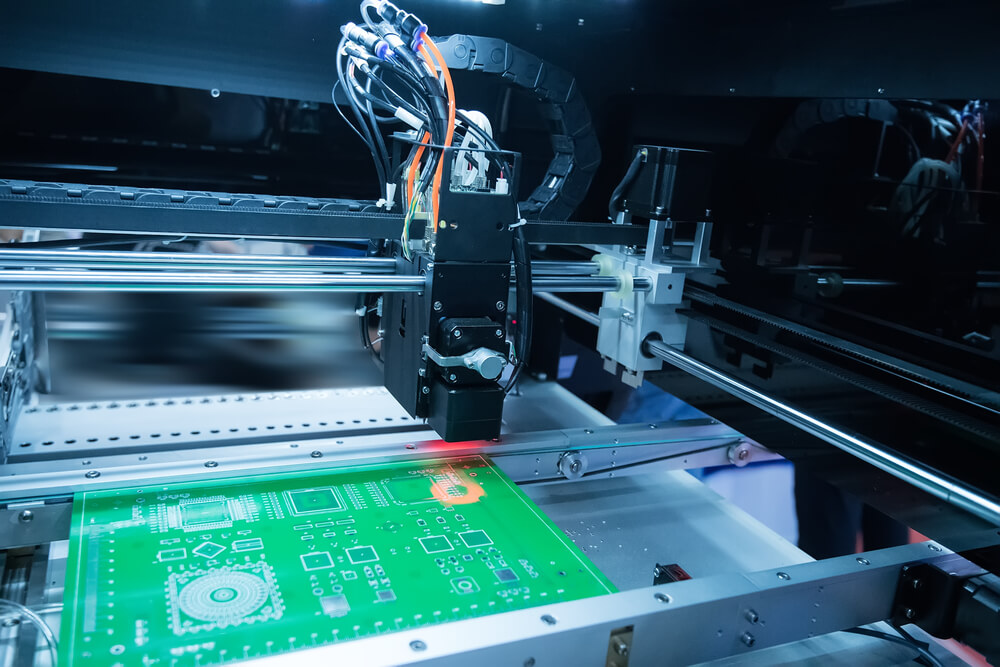

See PCBA Capability

Since components serve big importance in pcb assembly job, we do various material inspections and quality management records to ensure all parts are solid before and after the assembly.

We also perform primary inspections for components supplied by customers. All parts are stocked in good condition and spare parts shall be return to customers.

Or you may ask our procurement team to help sourcing all kinds of components, even for obsolete and hard-to-find ones.

- 3 shifts workers deliver within 7 wk days per standard project.

- Manual assembly within 3 days for quick prototype.

- 7 assembly lines with AOI as standard service,

- X- ray test is available upon customers requests.

Also AOI Discovery 8000 and Veri Smart Station are available.